Vial and Ampoule Counters guarantee an objective and precise counting of vials or ampoules in the trays. Specifically developed for the pharmaceutical field, Vial and Ampuole Counters, named MediaCount machine, allow to carry out the counting of vials or ampoules contained in the trays, both metallic or plastic, in a precise, automatic and traceable way. Thanks to a vision system especially designed and produced by Metapack, nowadays it is possible to have a tool that makes it reliable and objective counting vials and ampoules, operation that had not been automated yet until now.

WHAT VIAL AND AMPOULE COUNTERS ARE

Mediacount Machine is an autonomous counter machine with manual feed based on an artificial vision system, in which the operator enters the individual trays obtaining the automatic counting. After having counted, Mediacount generates a tag/label showing the amount of vials or ampoules detected therein: each tray can be identified with the specific datas of its relative content.

At the end of the batch, Mediacount provides a complete and detailed report of the processed trays number and of counting. Being arranged for a network connection, the machine can provide and exchange data through customer data infrastructure. In addition, Mediacount also verifies the presence of product irregularities, such as:

- Damaged vials and ampoules;

- Vials with non-compliant cap or fliptop;

- Tray areas with irregularity filling.

HOW VIAL AND AMPOULE COUNTERS WORK

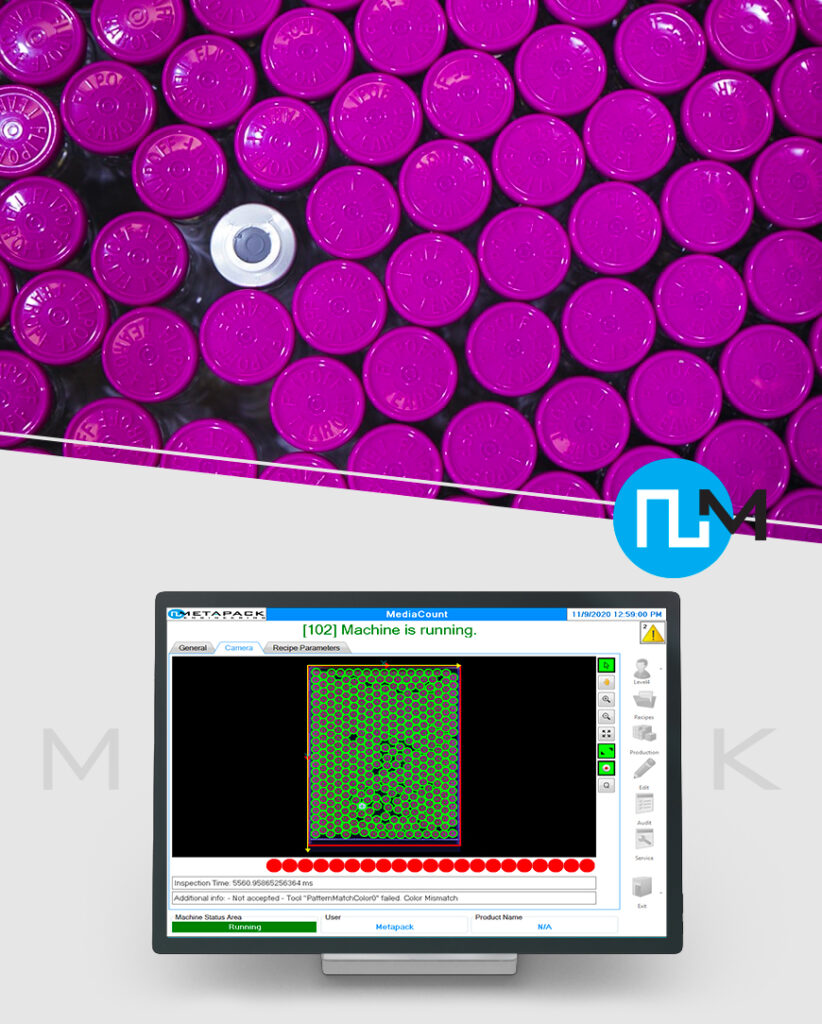

MediaCount is an artificial vision system that integrates a linear camera combined to a three axes handling system which allows to carry out high resolution images of the tray containing products to be counted. A special lighting system, applied with three axes on board of the systems, allows to acquire images suitable for counting. The vision software, designed ad-hoc with COGNEX technology, realizes a quick and precise counting and allows to alert the operator of product defect presence.

MediaCount software has been especially designed by Metapack to allow the operator to manage the control process in an easy and intuitive way. The machine can also be made for an automatic in-line counting.

OPERATIONAL PROCEDURE

- The operator logs into the system by entering the password.

- He/She selects the recipe and declares the beginning batch by inserting all production data.

- He/She starts by inserting the tray in the inlet mouth: the machine automatically completes the insertion of the tray inside it.

- The machine carries out the counting, displays it on the touchscreen along with the indication of possible faults of the product in the tray.

- The machine returns the output tray to allow the operator to pick it up and place the printed label.

- Steps 3-6 are repeated for all trays to be processed.

- When all trays in the batch have been processed, the operator declares the end of the batch.

Particular attention has been dedicated to MMI software, which assists the operator in each phase of the process, making the use of the machine very simple and intuitive.

TRAY IDENTIFICATION AND REPORTING

Vial and ampoule Counters are equipped with a printer for labels which are automatically produced at the end of each counting. The operator is therefore able to mark each tray with its identification data and contents. At the end of the batch processing, the machine produces a PDF or XML report detailing the trays processed. These datas may also be communicated by network to an IT infrastructure.